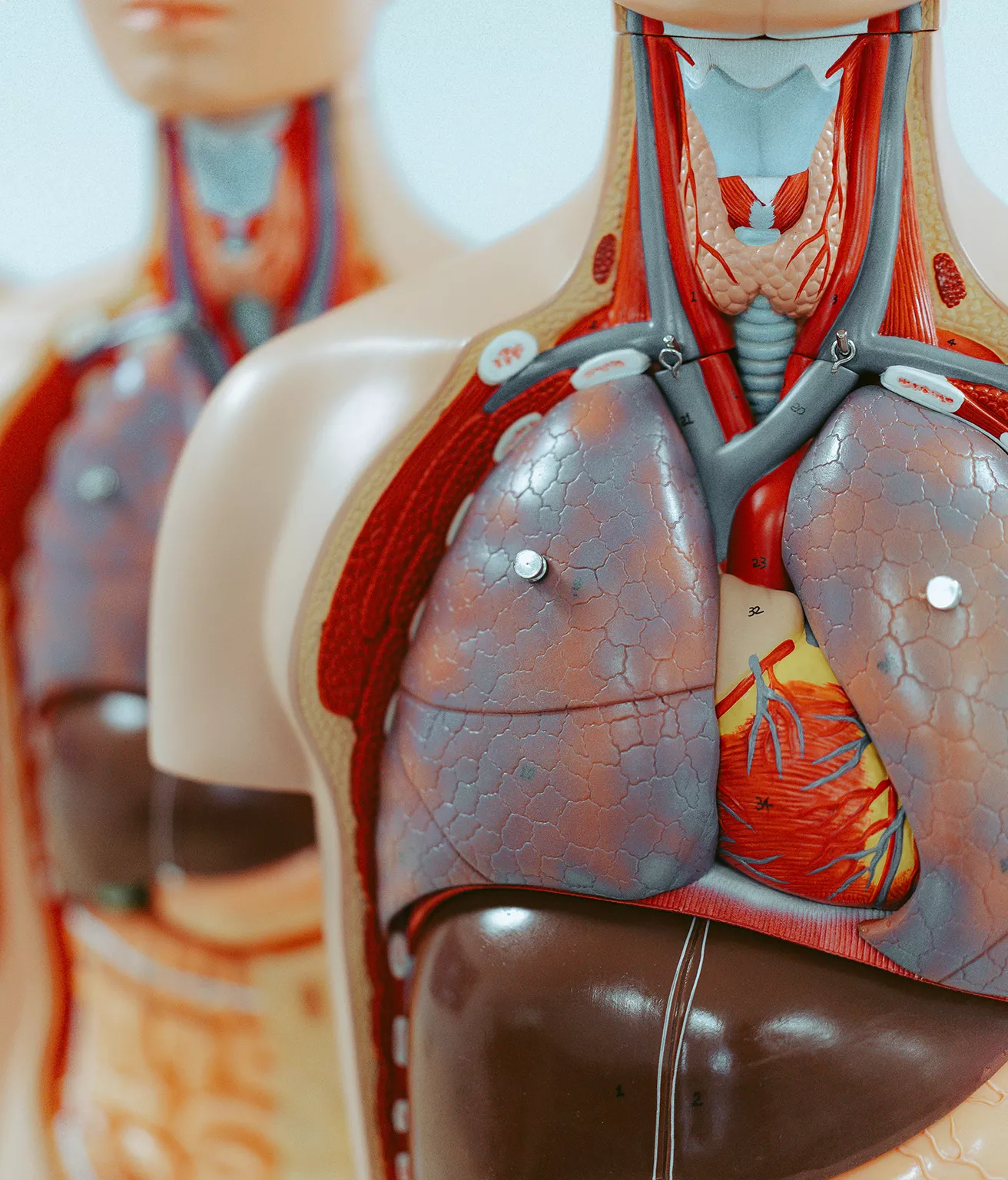

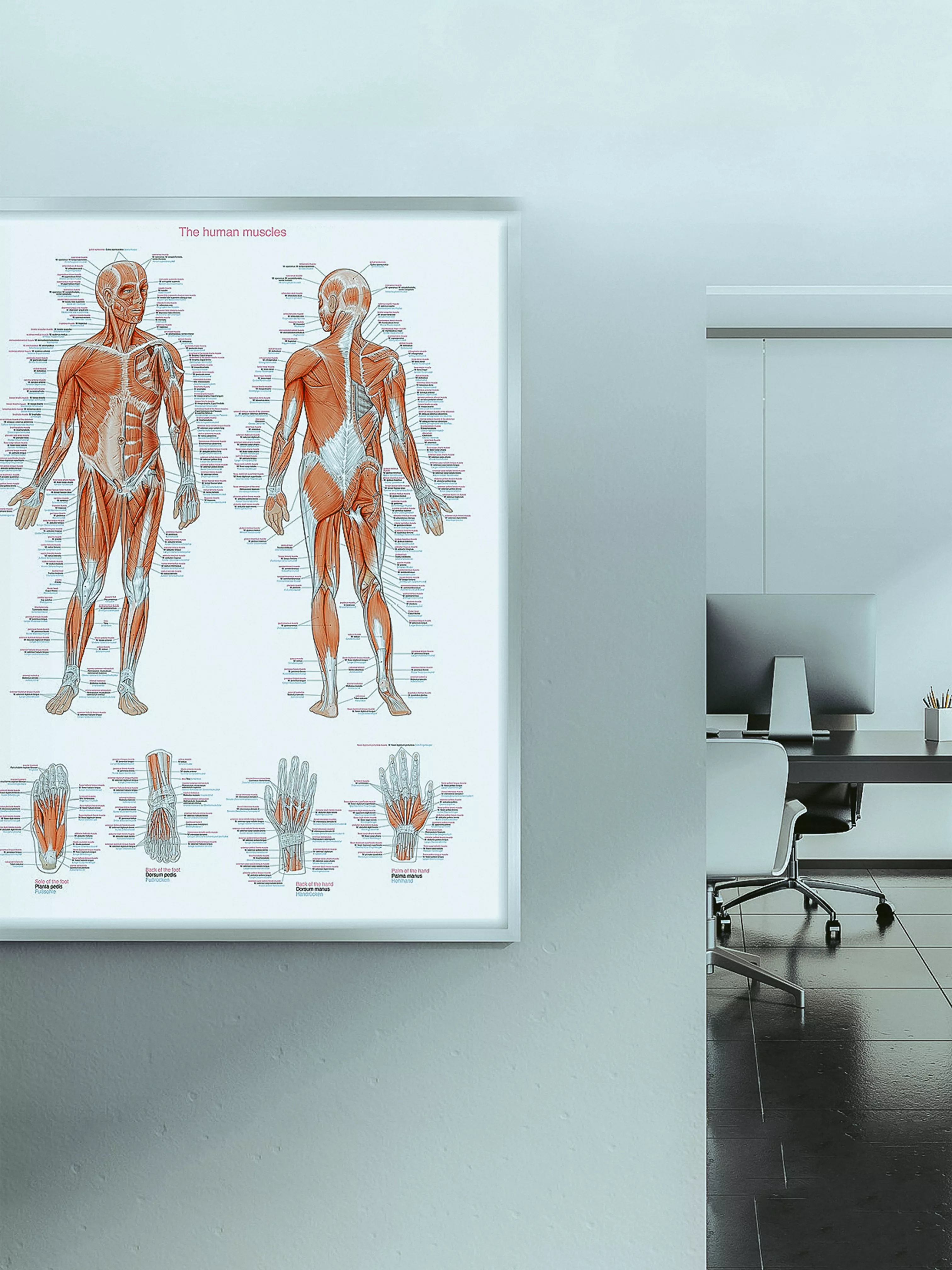

Product portfolio

Our quality speaks for itself

Discover our most popular products

The company

Erler-Zimmer GmbH & Co.KG

specialises in the production and marketing of didactic materials for science and medical education. The company was founded in 1950 and is based in Lauf, Baden Württemberg. The name Erler-Zimmer is made up of the surnames of the founder Johannes Erler and his son-in-law Walter Zimmer. Today, the company is managed by Ute Probst, Walter Zimmer's daughter, and her husband Walter Probst. Sons Mathias and Patrick Probst have been partners since 2015 and the company is 100% family-owned.

Erler-Zimmer GmbH & Co. KG

Manufacturer of fist-class

medical training aids

Good medical training saves lives!

We are aware of this responsibility. That is why we have been running a comprehensive range of high-quality training materials for more than 70 years, which are used successfully all over the world and contribute to improving the quality of training in all areas of medicine. The human body is a marvel of nature. We face the challenge of reproducing these complex structures as realistically as possible every day. All business processes are optimised so that errors can be virtually ruled out. However, customer satisfaction always takes centre stage. This means that processes can also be modified in response to customer requests, which makes us flexible and ensures maximum customer focus. In the manufacture of the products, each production step is subject to a quality check. Faulty parts do not even become finished products.

Continuous innovation

Social responsibility

Active customer orientation

Understanding quality

Sustainable actions

ISO 9001 certification

A passion for the sophisticated

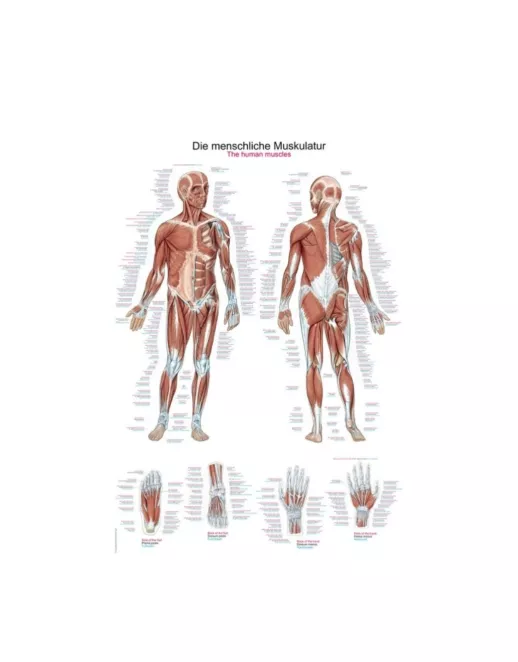

Our products are characterised by attention to detail, are always based on the latest scientific findings and are manufactured as realistically as possible using state-of-the-art processes. This results in fascinating replicas that fulfil the high demands of our customers at all times.

The latest technology - at the cutting edge

Modern product design with the latest CAD technologies. Various prototyping processes, including state-of-the-art full-colour 3D printing. Professional plastic production of all common materials. Suitable machine sizes for the economical production of a wide range of projects.

Our vision is our passion

As the 4th generation, we see it as our duty to supplement old values with a breath of fresh air. Growing up in the company, we learnt very early on that quality and customer orientation are not just words. For us, these are goals and values that we live by. Together with you, we would like to improve medical training and further education. We and the entire Erler-Zimmer team look forward to a lively co-operation. On our website, we would like to take you on a journey through one of the most extensive product ranges in the world.

Patrick Probst & Mathias Probst

Our vision is our passion

As the 4th generation, we see it as our duty to supplement old values with a breath of fresh air. Growing up in the company, we learnt very early on that quality and customer orientation are not just words. For us, these are goals and values that we live by. Together with you, we would like to improve medical training and further education. We and the entire Erler-Zimmer team look forward to a lively co-operation. On our website, we would like to take you on a journey through one of the most extensive product ranges in the world.

Patrick Probst & Mathias Probst

Augmented Anatomy App

Our anatomical models are supplied with a nomenclature. But this is not always to hand, which is why we now have a new app. It automatically recognises our models and displays the nomenclature in augmented reality with the model. The free app is also available for models that have already been purchased in the past; no special labelling is required on the model.

Read more

First-class quality in all products & processes

All business processes are optimised so that errors can be virtually ruled out. However, customer satisfaction always takes centre stage. This means that processes can also be modified in response to customer requests, which makes us flexible and ensures maximum customer focus. In the manufacture of our products, every production step is subject to a quality check. Faulty parts do not even become finished products.

Read more